The development of renewable energy in the United Arab Emiratesrequires not only solar panels or wind turbines, but also complex hidden infrastructure. It is the cable trays and cable management systems that have become the connecting element that ensures the safety, durability and efficiency of energy facilities. In conditions of high temperatures, dust storms, salty coastal air and constant wind loads, simple cable laying becomes unreliable. This is where the importance of well-thought-out systems manifests itself: they protect, organize, cool, and allow energy systems to scale without stopping.

Page Content

Cable Routes As A Stability Factor

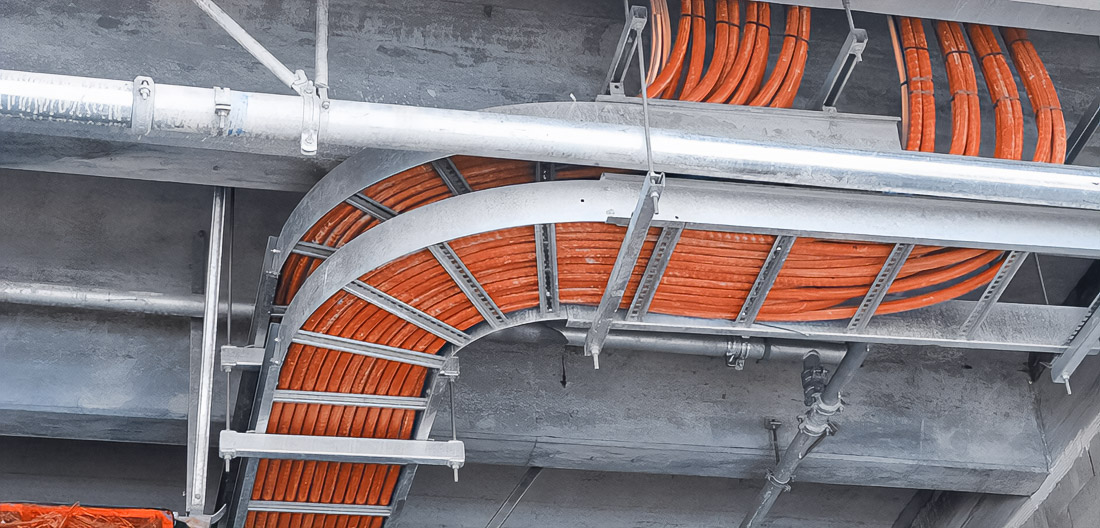

Solar power plants in open desert areas and offshore wind farms are subject to serious climate risks. Cable trays, whether ladder-type for heavy power lines or wire-type for control and communication systems, solve several tasks at once. They allow you to maintain optimal ventilation, eliminate overheating, and provide easy access for maintenance and upgrades. Cable channels with partitions separate DC and AC circuits, as well as low-current lines, including SCADA. All this together reduces the likelihood of accidents and reduces maintenance costs.

Materials And Their Role

The choice of material determines the service life of the system. Pre-galvanized steel is often used for indoor applications, providing sufficient protection at a low cost. However, in deserts and by the sea, hot-dip galvanizing (HDG) remains the standard, creating a durable zinc coating that is resistant to corrosion. Stainless steel grades SS304 and especially SS316 are used in areas with high environmental aggressiveness. In conditions of chemical exposure or high humidity, FRP, a lightweight composite that is resistant to corrosion and non-conductive, is increasingly being chosen. Aluminum trays have become an important solution for solar installations: they are lightweight, thermally conductive, fully recyclable, and ideal for roofs where every extra kilogram is important.

Regulations And Protection

Cable trays are required to comply with international standards: IEC 61537, NEMA VE1, ASTM A123, ISO 1461. This guarantees durability, load resistance and safety during operation. Fire-resistant cable tray accessories that can withstand up to ninety minutes in fire conditions are required for critical circuits such as emergency lighting and fire alarms. Continuous grounding must be provided during installation. Proper connection plates and flexible jumpers eliminate the danger of potential accumulation and ensure that protective devices are activated in case of an accident.

Installation Practices And Requirements

Installation errors can reduce the advantages of materials to zero. Excessive filling of the cable trays restricts ventilation and leads to overheating. It is recommended to observe a fill factor of no more than forty to fifty percent. The distance between the supports should not exceed one and a half to two meters for light loads, and even less for heavy loads. Thermal expansion of metal requires the installation of special expansion joints every twenty–five to thirty meters. Power cables are bent with a radius of at least eight to twelve diameters, and optical fiber is even more careful. These standards are not a theory, but a practical necessity for the climate of the Emirates.

Economics And Industry Trends

Investments in energy and construction directly boost demand for cable systems. In 2023 alone, 17.3 billion dirhams were allocated for engineering development. The global cable tray market has grown from $3.5 billion in 2022 to reach $6.2 billion by 2030. The Middle East and Africa region is projected to grow to $2.7 billion by 2025, with an average annual rate of about seven percent through 2033. The wire tray segment in the Emirates will increase from $11.54 million in 2024 to $17.45 million by 2032. These figures do not just show the growth of the market, they reflect the strategic importance of reliable cable management for the future of energy.

Sustainable Development And Future Outlook

The role of cable systems goes far beyond the organization of wiring. They maintain energy efficiency, provide ventilation and heat transfer, reduce operating costs and extend the service life of equipment. The use of recyclable materials such as aluminum and the transition to environmentally sustainable solutions are fully consistent with the country’s development goals. In the coming decades, proper integration of cable trays will ensure that solar farms, wind farms, and energy storage systems operate stably and safely.

Cable trays have ceased to be an “invisible” part of the infrastructure. Today, they are the foundation without which it is impossible to build a reliable, scalable and environmentally friendly energy industry in the UAE.